Heavy-Duty Pipeline Rehabilitation for Industrial Infrastructure

Industrial townships, factories, and large manufacturing hubs rely heavily on a complex network of underground pipelines — including effluent discharge lines, stormwater drains, utility ducts, and chemical-carrying pipelines. These pipelines face relentless operational stress due to high pressure, abrasive materials, chemical reactions, and fluctuating temperatures.

Over time, these essential pipelines begin to corrode, develop cracks, or collapse entirely, leading to frequent breakdowns, leaks, waterlogging, and in some cases, serious environmental violations or factory shutdowns. Excavating and replacing these pipelines manually isn’t just costly — it’s often unfeasible due to limited downtime and heavy machinery movement aboveground.

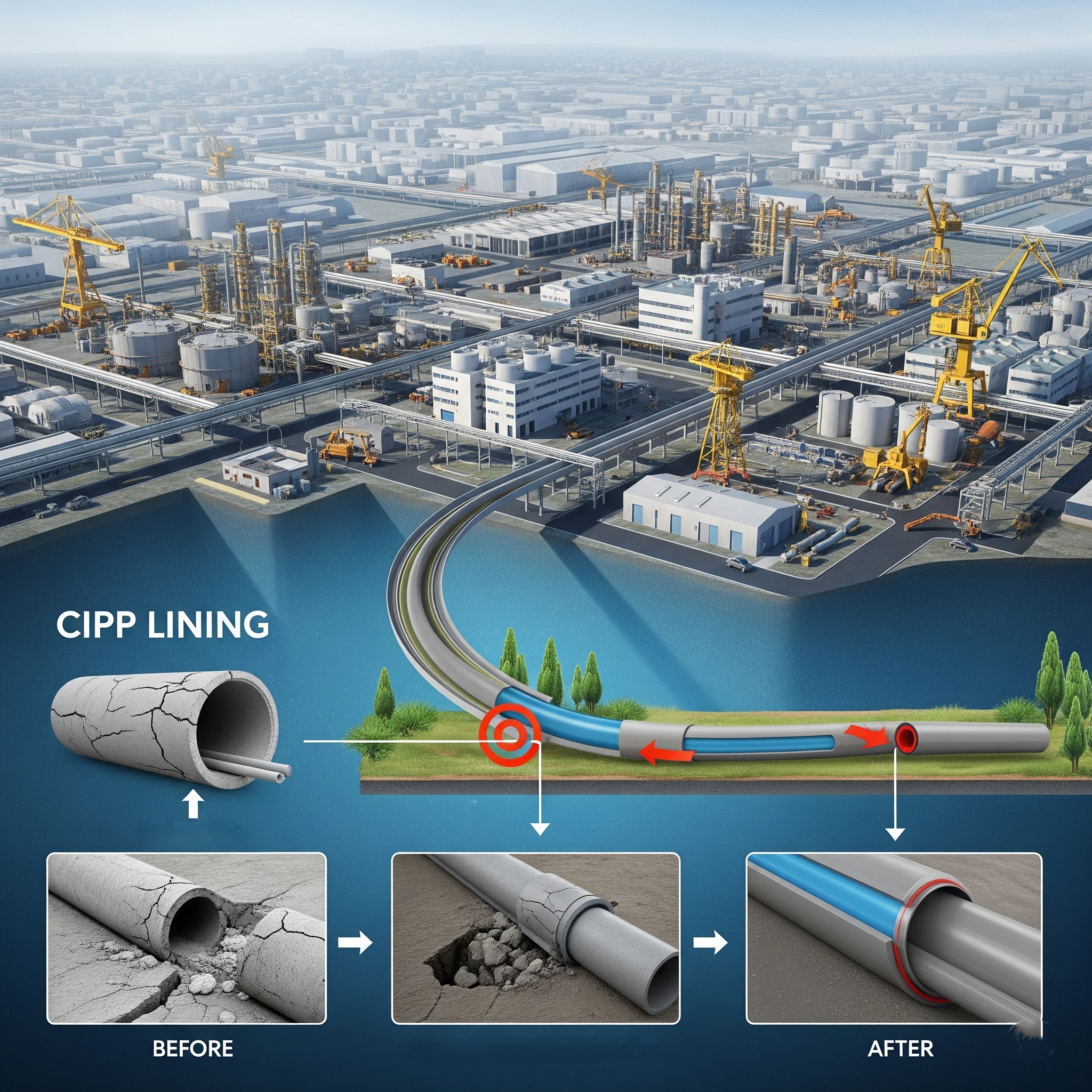

That’s where Pipe Care Services steps in. We provide engineered Cured-In-Place Pipe (CIPP) and trenchless point repair technologies tailored for industrial-grade infrastructure. Without disrupting plant operations, halting production, or breaking factory flooring, we restore damaged pipelines from the inside, enhancing flow capacity and structural integrity for decades.

The Industrial Drainage Challenge

- 🧪 High-flow effluent lines exposed to chemical erosion

- 💥 Pipe bursts from pressure surges in utility corridors

- 🛢️ Oil and grease clogs in stormwater channels

- 🌧️ Rainwater backups due to industrial debris or sedimentation

- ⚖️ Non-compliance with environmental discharge regulations

- 🏭 Inaccessibility due to continuous machine or worker operations

How Pipe Care Services Supports Industrial Infrastructure

-

🧵CIPP Lining for Long-Run & Large-Diameter

Pipes We install resin-soaked felt liners within degraded pipelines and cure them using UV, hot water, or steam — forming a seamless, jointless new pipe that lasts over 50 years. Ideal for pipelines ranging from 30mm and more diameter pipes. -

🩹Trenchless Point Repair

For localised damage, our point patch solutions fix isolated defects (like cracks or offsets) without relining the full pipe — saving both cost and time. -

🤖📹Robotic CCTV Pipe Inspection

We deploy motorized crawler cameras that travel up to hundreds of meters inside pipelines, delivering live visuals and recorded footage for damage assessment and compliance reporting. -

💨High-Pressure Jetting & Cleaning

Our industrial-grade jetting units clean stubborn deposits, chemical residues, and silt — restoring full pipeline diameter without the need for excavation. -

🗺️Pipeline Mapping & Documentation

We provide GIS-based mapping, condition assessment reports, and compliance-ready documentation — vital for regulatory inspections and audit trails. -

🧪🔥Chemical & Temperature-Resistant Resins

Our CIPP systems can handle high-temperature effluents and corrosive waste using specialized resin blends, including UV-cured liners for faster turnaround.

Why Industries Trust Pipe Care Services

- 🏭 Zero Disruption to Ongoing Production – Work completed without halting plant activity

- ⏱️💰 Reduced Downtime & Maintenance Cost – Trenchless tech eliminates long shutdowns

- 📹✅ Compliant & Documented Repairs – Full video reports and repair logs

- 🧪🔥 Designed for Harsh Environments – Handles high pressure, temperature, and corrosive flows

- 🛣️ Scalable for Long-Distance Pipelines – Ideal for factory-wide or multi-building networks

Ideal for Use In:

- 🏭 Heavy manufacturing facilities

- ⚙️ Engineering & fabrication units

- 🧪💊 Chemical & pharmaceutical plants

- 🛢️ Oil, paint, and petrochemical processing zones

- 🌾 Agro-processing and food industrial parks

- 🗺️ Public and private industrial estates (SEZs, EPZs, etc.)

- 🏛️ Government-owned industrial colonies or PSUs

Pipes We Commonly Rehabilitate

- 🧱 RCC and concrete effluent lines

- 🧪 HDPE or steel chemical pipelines

- 🌧️ Cast iron and GI stormwater drains

- 🔗 Underground utility conduits and lateral connections

- 🚰🛢️ Dual-pipe networks (clean & contaminated water systems)