A Case Study CIPP (Cured in Place Pipe) an answer to Infiltration/exfiltration

1. What is it?

The cured-in-place pipe (CIPP) lining process involves the insertion of a chemicalsaturated flexible lining material into an existing sewer pipe. Air or water under pressure is forced into the tube, which turns the lining inside out and causes it to expand to fit tightly against the existing sewer walls. Hot air or water is circulated throughout the tube to cure the resin. When the curing process is completed, a new “pipe-within-a-pipe” is created, eliminating cracks and holes that allow ground water/rainwater and roots to enter the sewer and cause operational problems such as infiltration, stoppages and overflows.

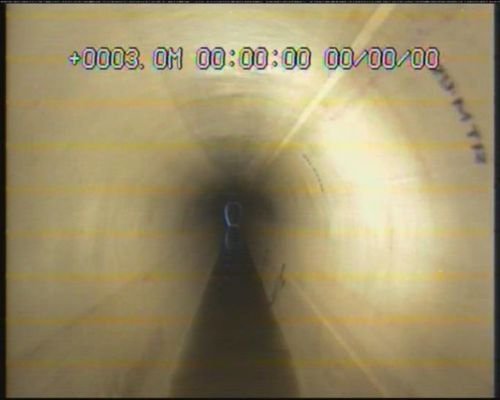

The sewer must be prepared for lining; this includes removing roots, sediment and grease from the sewer and cutting out intruding connections. The sewer then is inspected using closed circuit television (CCTV) and the locations of connections from homes and other properties noted. Manholes also are inspected. Like many other forms of pipe renewal/replacement, CIPP requires bypass pumping, which re-routes sewer flow around the segment being worked on during installation. Cured-in-place lining can be manufactured to suit many shapes and can accommodate small deformations and changes in the direction of the sewer.

The CIPP liner thus installed makes a jointless/seamless, stand alone, fully structural pipe within the pipe, increasing the flow carrying capacity of the pipe and life by more than 50 years.

2. Salient Features

- CIPP is the world’s most popular method for trenchless rehabilitation

- This method is highly suitable for potable water mains and pressure pipes too

- This is applicable to and has been successful for all shapes and diameters

- The guaranteed life of the liner is 50+ years

3. Advantages of CIPP

The following are the top 10 advantages to using cured-in-place pipe repair:

- There is very minimum diameter loss and the new pipe is stand alone and fully structural

- No damage to floors, structures, sidewalks, interior walls, landscaping, or streets

- 100% trenchless technology used

- Massive increases in flow efficiency

- Elimination of root intrusion

- Repairs pipes with multiple angles and bends

- Significant cost savings and alternative to costly and unsafe pipe replacement

- Stops leaks and infiltration

- Prevents root intrusions

- Saves treatment and pumping costs.

4. It’s quick and safe!

- The process of rehabilitation using CIPP is very fast

- Involves no excavation or very minimum excavation

- Causes minimal disruption to traffic

SUMMARY OF CASE STUDIES

1. RAMPUR SEWER (CLIENT – U. P. Jal Nigam)

2. GEORGETOWN SEWER (CLIENT – U. P. Jal Nigam)

3. BAIRAHANA SEWER (CLIENT – U. P. Jal Nigam)

4. CHANDNI CHOWK (CLIENT – Delhi Jal Board)

RAMPUR

The sewer line of 700 mm dia. Using RCC NP3 was laid in Rampur city, which was connected to the sump well in the treatment plant. For some reasons the sewer line could not be commissioned for about 7/8 years and by the time the infrastructure was ready for the sewer to be commissioned, sewer line started settling, due to heavy ground water infiltration. This infiltration caused the send to flow in with the water causing the ground above the sewerline to settle posing the danger to nearby residential houses and buildings. Also the road had to be closed for traffic due to frequent settlements.

Onsite India, being the expert in such emergency services was approached by U. P. Jal Nigam to study the problem and rectify the same immediately, as the monsoon was approaching soon and the department had the pressure to commission the line urgently so that the entire sewage could be treated to reduce the pollution in the river.

An expert team of engineers was deputed on site to start the work the same day upon getting the confirmation from the department. The strategy, in consultation with the department engineers, was made so that the job could be completed within the specified time. The part of the strategy was to do the conditional assessment of the affected sewer line first using CCTV camera. Upon the condition assessment it was found that the pipeline had very wide open joints giving the free passage to the ground water to flow inside carrying the sand along.

After finishing the condition assessment, it was decided by the department to rehabilitate the sewer line using CIPP technology. Now the next challenge was to install the CIPP liner inside the pipeline as the infiltration was continuous. And if there was a time gap between cleaning and liner installation the pipeline will be filled back again with sand which will find free space to flow in with the water. Therefore, it was decided to install the liner immediately after cleaning. The size of the host pipe was measured at the mouth of the manhole to design the liner. The liner was kept ready at site by the time the cleaning was supposed to be complete for the particular stretch between two successive manholes. The process of liner installation was immediately started as soon as the cleaning was complete. However, the infiltration was so heavy that cleaning by high pressure water jetting machine and installation of the liner was done parallelly.

The next challenge was the preparation of the CIPP Liner, as we had all the machinery and plants in Delhi, and there was hardly any time to shift the entire setup to Rampur, which was not only time taking but costly also. Therefore, it was decided to transport the impregnated liner from Delhi to Rampur. The liner temperature has to be maintained below 30oC till the liner is installed and maintaining that in the month of June was very challenging. Finally this was made possible by a hardworking, very well experienced and dedicated team of engineers and other team members.

Finally the project was completed successfully before the targeted date

Diameter: 700mm

Depth of sewer:4/5 meters

Pictures showing ground water infiltration and sand flowing with it and open joints

Post Lining Images of Rampur Sewer

GEORGETOWN & BAIRAHANA, Allahabad (Uttar Pradesh)

The historic town of Allahabad (now called Prayagraj) and also known as the Sangam City is known for its dense population, congested roads and the famous Kumbha Mela, where thousands throng to take a holy dip in the Ganges. Also with the influx of more and more people everyday demand for support services like water supply, drainage, sewerage, garbage collection and disposal is rising alarmingly.

Massive amount of per capita waste from domestic and industrial activities are generated and allowed to be discharged into the Ganga river without being treated, thus polluting not only the water and creating various kinds of diseases but also the biodiversity of the river was being badly effected. The lack of periodic maintenance and the renovation of the old sewerage systems created further problems for the city.

Emergency to rehabilitate the two sewers of Georgetown and Bairahana had risen just before the huge event of Kumbh Mela due to the same problem of ground water infiltration and blockage at various areas due to which there would be overflow and flooding in the low lying areas causing unhealthy environment. Onsite India was awarded the work of rehabilitation of Bairahana which was specially the main sewerage of the district, which had all the flow coming into it and making it hundred percent silted and a massive volume to control. Due to lot of “petha” (Indian sweet) manufacturing units releasing their wastes into this sewer it had a lot of calcium deposits making it particularly difficult for us to work. To top all this the areas were extremely congested, sewers passing mainly under the bylanes of the residential areas.

GeorgeTown

Bairahana

Our team was posted on a war footing to conduct the CCTv survey and report immediately regarding the status of pipes and we took action immediately. Slowly and gradually the situation started showing improvements and the clients from Uttar Pradesh Jal Nigam were convinced and satisfied .Now both the sewers have been rehabilitated and operating well.

Post Lining images of Bairahana Sewer

CHANDNI CHOWK, Delhi

Chandni Chowk is one of the oldest and busiest markets in Old Delhi, India, which is of great historical importance too. It is located close to Old Delhi Railway Station which is one of the busiest railway stations in our country. The Red Fort monument is located at the eastern end of Chandni Chowk making it one of the heritage sites of the capital. It was built in the 17th century by Mughal Emperor of India Shah Jahan and designed by his daughter Jahanara. The market was once divided by canals (now closed) to reflect moonlight and remains one of India’s largest and busiest wholesale markets.

At present, even till a few days back Chandni Chowk was a messy market place with both modern and historical residential areas around it teemed with peddlers, street vendors and street food.

The Honorable Chief Minister and the Delhi state government took upon itself to restore the beauty, grace and heritage of Chandi Chowk to its initial grandeur. Onsite India was awarded the work of rehabilitation of the Chandni Chowk sewer line. Chandni Chowk suffered from huge water logging due to its old sewers laid during the British times and internally the 98 % silted sewer also showed infiltration problems. When we started working we expected a dia of 750 mm as awarded to us but as work progressed an altogether different size was discovered forcing a total changing in strategy and budget. Not only this the sewer was egg shaped as shown in the pictures below and hence their liners were designed in a different way considering different factors.

We faced all kinds of issues while working in Chandni Chowk, space constraint being the most important. Working in tandem with a lot of other government agencies, securing permissions, closure of work for independence day and finally for pollution control by NGT orders – we have faced it all.

Post Cleaning and PreLining Ling condition of the Chandni Chowk Sewer as highlighted by our CCT camera

But finally the hard work patience and expertise coupled with world class raw materials and the most experienced man power in the industry ensured the perfect and the best of results. The finished liners were very much appreciated on inspection and look as below

Currently Chandni Chowk looks beautiful as below and the work that we have done has not only been appreciated but also been widely covered by the print media.(Reports attached at the end of the document)

N. M Joshi Marg, Mumbai

The sewerage system of Mumbai, the financial capital of India is a century old and the city experiences massive rains every year. Last year however the season’s entire rainfall was received in just 21 days, water logging in all low lying areas including N.M Joshi Marg where the Brihan Mumbai Municipal Corporation has been promising relief to residents, users and commuters for long but to no effect. N. M Joshi Marg was under 8 to 10 inches of flood water and life almost comes to a standstill every year. Onsite India was awarded the work of rehabilitation of this sewer. Our team reached the site for a CCTV survey and the images from the survey have been furnished below. The line had multiple problems like ground water infiltration, deformity, intruding roots to mention some. A 50 meters stretch in this line was totally cracked and could have collapsed any moment. Our team took immense care to survey down this area but finally we were successful in producing the entire footage to the BMC who decided to rehabilitate this as soon as possible to save themselves and the civic life from immense amount of catastrophe.

Post Rehabilitation a pipe inside the broken pipe could be created and the required support was provided to the existing pipe which was at the onset of collapse.